With Our Real-Time Quality Checking Software

Streamlined workflow and optimized resource allocation

With Our User-Friendly Quality Checking Software

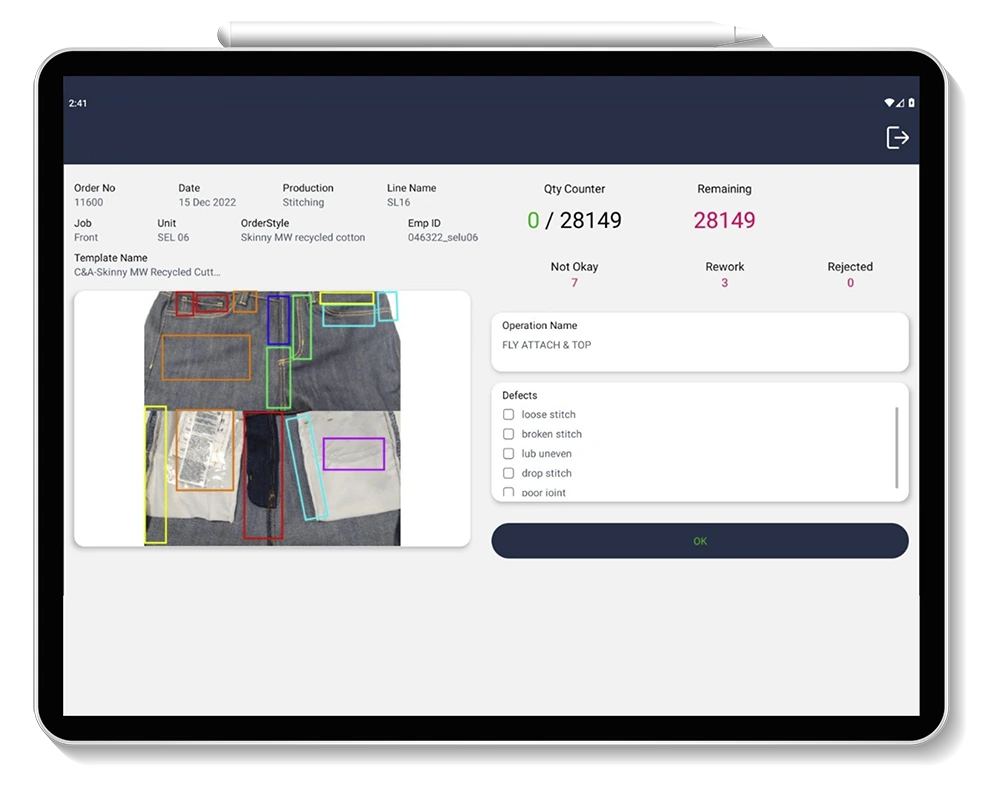

User-friendly mobile and tablet-based interface for easy use by production line workers

Scalable and customizable for businesses of any size

Why Niddle Pack?

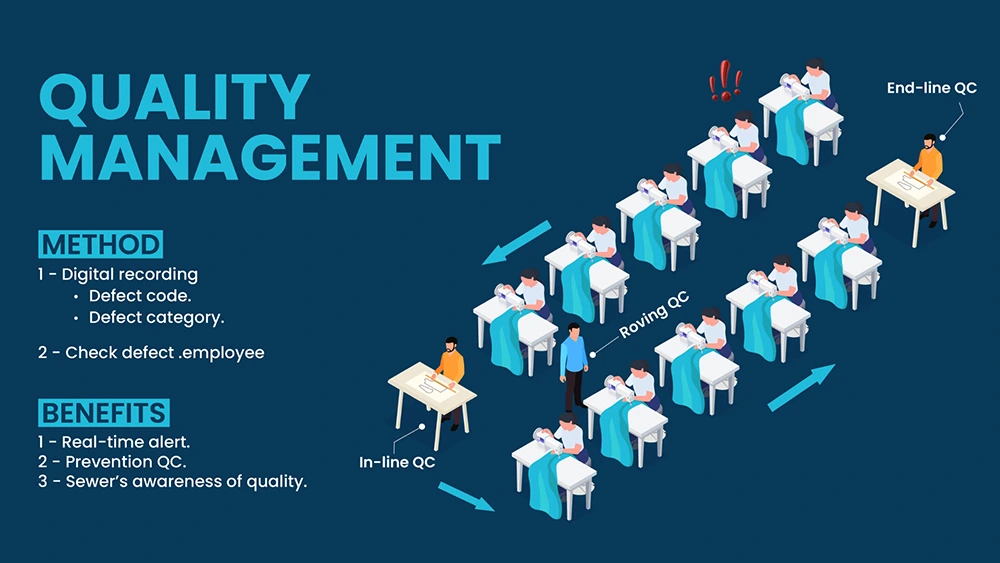

The software is a real-time quality-checking solution for garment production lines. It provides a mobile and tablet-based solution that is user-friendly and requires no paperwork, making it easy for workers on the production line to use. The software includes standard operating procedures for checking and defect tracking, as well as detailed tracking of each garment produced, to help improve the overall quality of the final product.

Have an Idea?

Take your business to the next level! Get in touch now!

Benefits

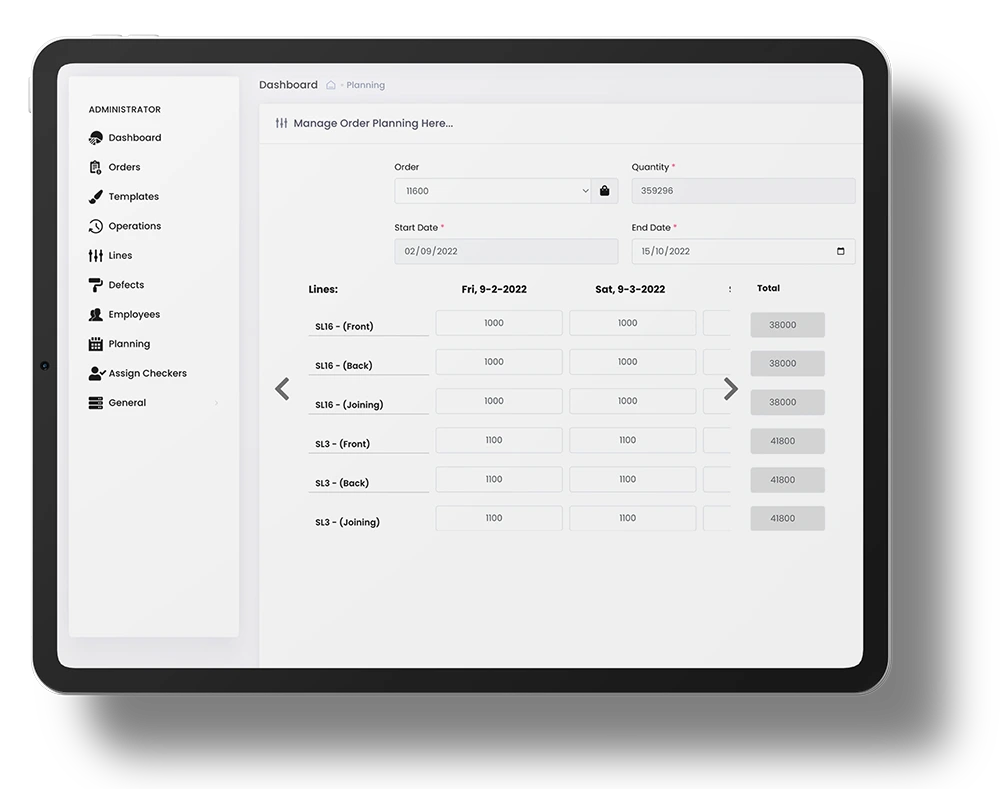

The management portal provides real-time insights into the garment production line and allows for real-time monitoring of the production line and its progress. The software also includes modules for factories to run their own audits, allowing them to monitor their own performance in real-time and improve accountability.

Real-time Quality Checking

- Monitors the garment production line in real-time

- Helps to reduce the number of defects and improve the overall quality of the final product

- Enables the early detection and resolution of quality issues, such as seams coming undone or incorrect stitch patterns

Management Portal

- Provides real-time insights into the garment production line

- Improves decision-making and the efficiency of the production process

- Allows for real-time monitoring of the production line and its progress

Have an Idea?

Take your business to the next level! Get in touch now!

SOPs for Checking and Defect Tracking

- Includes standard operating procedures for checking and defect tracking specific to garment production

- Provides deeper insights into the garment production process

- Improves the identification and resolution of quality issues, such as fabric shrinkage or dye issues

User-Friendly with Zero Paperwork

- Designed to be user-friendly and requires no paperwork

- Easy for workers on the production line to use

- Helps to reduce the risk of errors and improve efficiency, particularly in terms of reducing manual record-keeping

Have an Idea?

Take your business to the next level! Get in touch now!

Item-Level Traceability

- Provides detailed tracking of each garment produced

- Improves accountability and reduces the risk of lost or missing items

- Enables the identification of production issues at the item level, such as incorrect size or labeling

Modules for Factories to Run their Own Audits

- Includes modules for factories to run their own audits

- Allows factories to monitor their own performance in real-time

- Improves accountability and reduces the risk of errors, particularly in terms of ensuring consistent quality control standards

Mobile/Tablet-Based for Convenient Use

- Mobile and tablet-based for easy use on the production line

- Improves efficiency and reduces the risk of errors by allowing for real-time monitoring and data input

Have an Idea?

Take your business to the next level! Get in touch now!

Dashboard Reporting over the Cloud

- Includes a dashboard for reporting over the cloud

- Provides real-time insights into the garment production process

- Improves decision-making and the overall efficiency of the production line by allowing for easy analysis and reporting of production data

Real-Time Production Tracking

- Helps to control rejection, rework, and lost garment

- Improves the overall efficiency of the garment production process

- Reduces the risk of waste and improves accountability by enabling the identification and resolution of production issues in real-time

Control Rejection, Rework, and Lost Garment

- Helps to control rejection, rework, and lost garment

- Improves the overall efficiency of the garment production process

- Reduces the risk of waste and improves accountability by enabling the identification and resolution of production issues in real-time

Feeling for Marketers

- The system show real-time data to different business group segments

- To see the quality of product at every stage.

- To management the error and deliveries

- To focus on customer commitment

- Enterprise level application to show real-time audit details of different stage of production life cycle.

Have an Idea?

Take your business to the next level! Get in touch now!